Metal Properties: Toughness

Toughness is a mechanical property that measures the amount of energy a material can withstand, or absorb, before fracturing. In the context of other mechanical properties, toughness for steel products represents a balance of strength and ductility.

As a material term, toughness can sometimes cause confusion: two very different materials can both be considered tough. For example, an iron anvil is tough because its strength is very high, and it resists fracture by maintaining its material integrity thanks to its strength. On the other end of the spectrum, silly putty is also a tough material, not because it’s strong but because it’s very ductile and will resist fracture until you pull it far enough apart that the two ends separate. Anvils and silly putty are very different, but they’re similar in that they are both tough, and they both absorb a good deal of energy before fracturing.

Heat Treatment: Annealing

The heat treatment known as annealing encompasses a group of processing heat treatments. Unlike thermal processes that are used to improve the strength and wear resistance of a part (such as hardening heat treatments), processing heat treatments are used to prepare a workpiece for further manufacturing processes. Chiefly, this means improving a material’s responsiveness to machining or cold-working by restoring (and even enhancing) ductility.

After an annealing process, the part can be expected to go to the machine shop for additional subtractive manufacturing, or to a mill to be cold worked. In fact, annealing makes machining and cold working easier (even possible) by relieving internal stresses, reducing hardness, increasing ductility and toughness, and softening the material to make it more machinable and workable.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Quenching

Imagine a medieval blacksmith hammering a sword fresh out of the fire. With the weapon still red-hot, he dunks it in water. The water hisses and boils around the submerged steel as it turns color from glowing orange to grey. This iconic scene of rapidly cooling a workpiece is called quenching, or quench hardening, and is one of the oldest and most common heat treatment processes used to harden and strengthen common carbon steels. In modern metallurgy, superior corrosion resistance for most stainless steels is also an important property achieved through quenching.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Stress Relief

Internal stresses form naturally during many manufacturing processes. Machining, stamping and welding, for example, are common manufacturing methods that augment the amount of stress in a material’s fabric. And although stress build-up is a natural byproduct of these processes, too much of it leads very commonly to part distortion. Most of these stresses must therefore be removed before a part can be considered ready and safe to use. Thanks to heat treatment, these stresses can be relieved (without changing a part’s mechanical properties) through a thermal process known as stress relieving.

Tags: Processes, Metallurgy, Heat Treatment

Metal Properties: Weldability

Joining multiple metal parts together into a single, cohesive unit is an indispensable process to manufacturing. Bolts, screws, and adhesives are often used to unite separate parts, but many applications call for a more solid connection. Thanks to the craft of welding, manufacturers are able to effectively create a single part from multiple components. Casting facilities are also able to use welding to repair minor casting defects, improving overall process efficiency and reducing part cost.

Understanding the weldability of various alloys is key to creating welds that last and parts that perform in the field. As a mechanical property, weldability is also an important consideration in designing and producing cast parts.

Tags: Welding, Metallurgy, Metal Properties, Mechanical Properties

Heat Treatment: Hardening

Hardening a metal achieves much more than simply making it mechanically harder. It also improves strength, making the alloy more resistant to plastic deformation, and can aid with corrosion resistance. However, a harder metal is also often a more brittle metal. As such, hardening is usually just one part of a properly designed heat treatment plan.

Because hardening can be accomplished through numerous heat treatment strategies, it’s important to know what options are available to a casting customer, how the methods differ, and where hardening fits into the master plan.

In this article, we’ll explore the science and practice of hardening, and explain when conditions are appropriate for a particular hardening strategy. Whether you’re working with the Eagle Group or another metal manufacturer, hardening is an important step in manufacturing, so it’s good to know the basics.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Normalizing

Normalizing is one of the most common heat treatments used in manufacturing carbon steel. It is a vital process to ensure that the mechanical and physical properties of a carbon steel workpiece are integrated and distributed uniformly across the material.

In steelmaking, material uniformity is achieved by carefully controlling a casting’s microstructure – specifically, its grains. Grains are distinct areas of crystal structures oriented in the same direction. Multiple grains together make up a metal’s structure. The goal of normalizing is to target these grains in order to even out the differences between them, resulting in a more mechanically stable product. It’s for this reason that the process is named as such: it ‘normalizes’, or homogenizes, grain size, shape, and orientation.

Tags: Processes, Metallurgy, Heat Treatment, Normalizing

Keeping Castings Made in America: Supporting the American Foundry Industry through Entrepreneurship

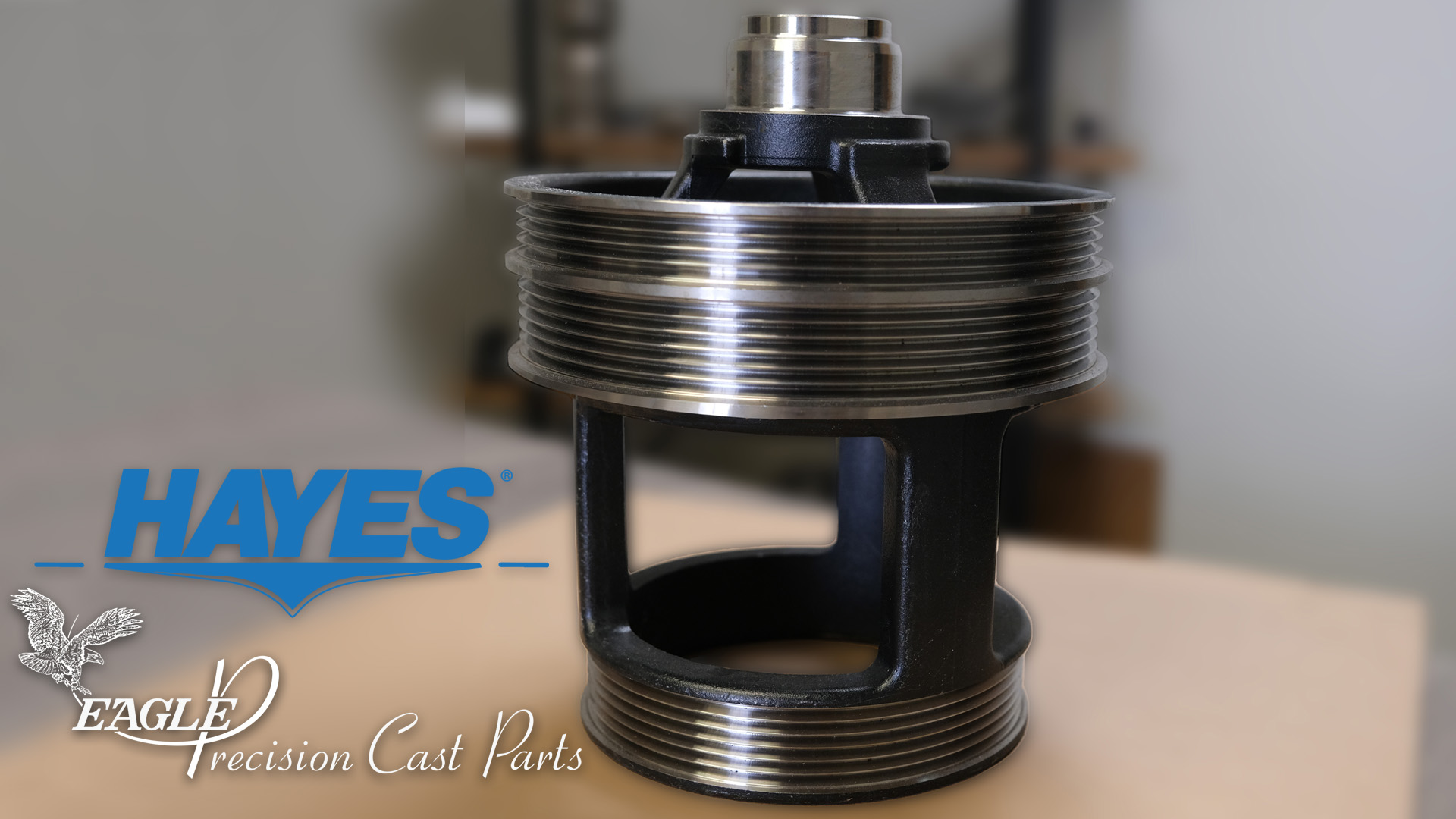

The Eagle Group is a team of manufacturing companies based in Muskegon, MI, made up of three foundries and a machine shop. Eagle Alloy, Eagle Aluminum, Eagle Precision and Eagle CNC are connected through common ownership and through common goals: while each company occupies its own niche, they often work together to provide “concept to completion” manufacturing. Beyond these four companies, Eagle Group’s owners also have stakes in OEM companies that utilize the Eagle Group’s services, but occupy altogether different spaces in the manufacturing world.

Tags: Case Study

Miracle in Muskegon: How the Eagle Group Replicated a MiG 17F Fighter Jet Fuel Cap in Two Days

When a star jet pilot had a missing fuel cap at the Muskegon Air Show, the Eagle Group stepped in to replicate the part in less than 48 hours.

Wings Over Muskegon took place in July, 2023 at the Muskegon County Airport. This interactive aviation experience was a revamped version of the Muskegon Air Fair, and marked the first event of its kind held in Muskegon in 17 years. Spectators enjoyed aerial acrobatics, flybys from iconic planes like the B-52 Flying Fortress, and even rides in WWII-era planes and Vietnam-era helicopters. Our very own John Workman, Eagle Group co-chairman of the board, performed at the event with his formation flying team, the Hooligans.

Tags: Case Study

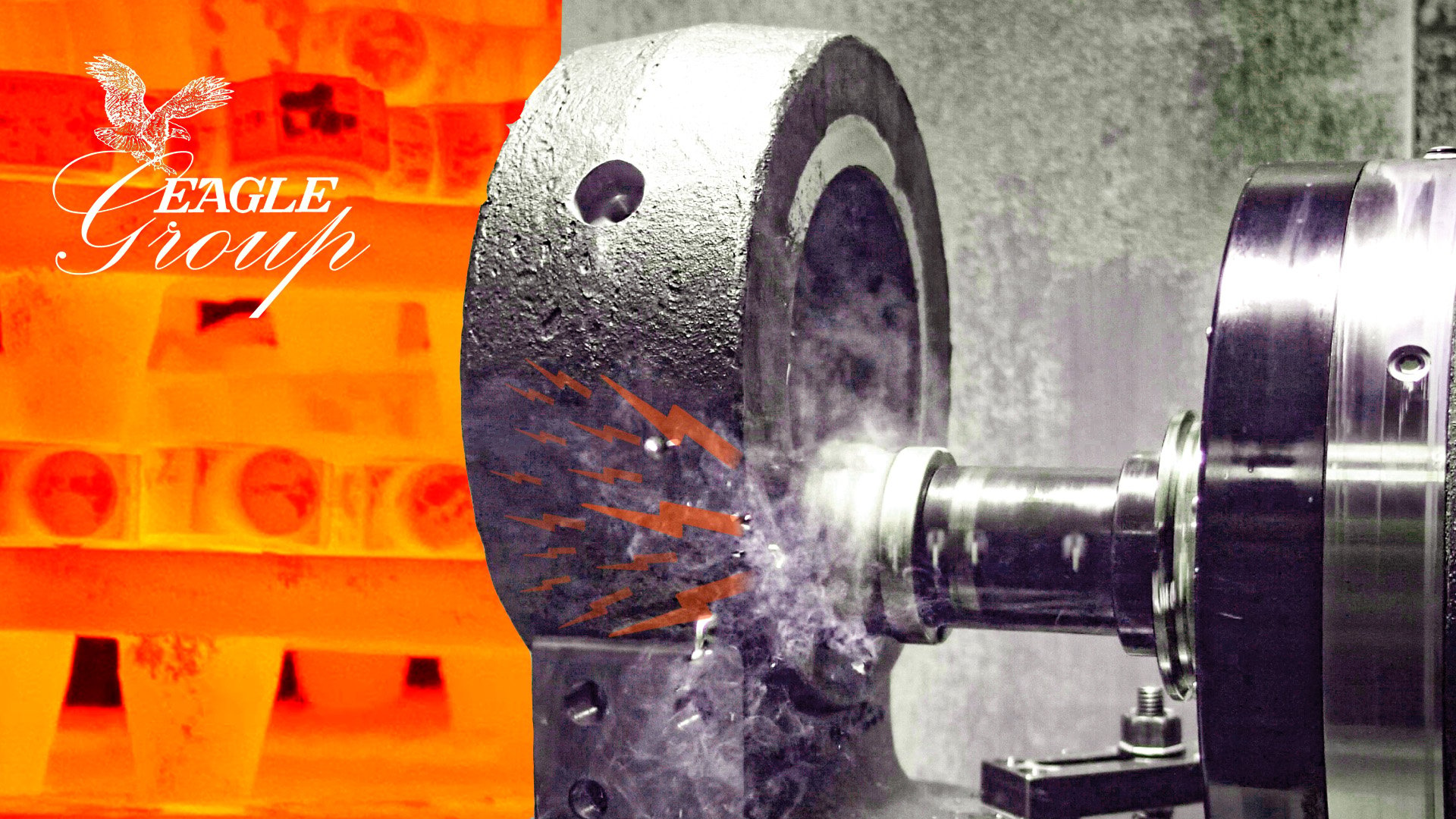

Case Study: Converting a Fully Machined Part to an Investment Casting

Manufacturers are aware of the benefits of machining: trained machine shops can produce complex parts with tight tolerances and all critical surfaces to spec. However, many manufacturers are learning that investment casting can produce cast parts to near-net shape, resulting in a host of benefits.

The machining process is often seen as the only way to manufacture a part with highly demanding specifications. Operating under this assumption, manufacturers sometimes choose to machine default without exploring other options. It’s also common for parts to be ‘over-toleranced,’ meaning they’ve been designed with tighter tolerances than the application actually calls for.